|

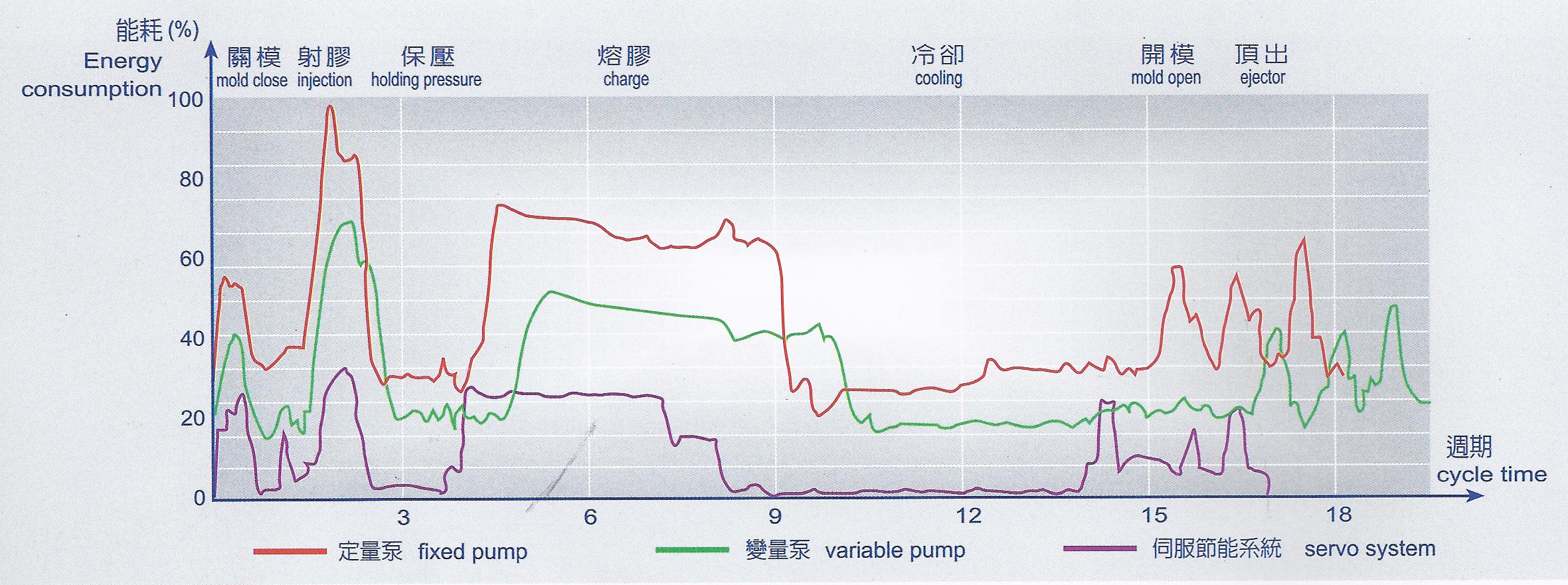

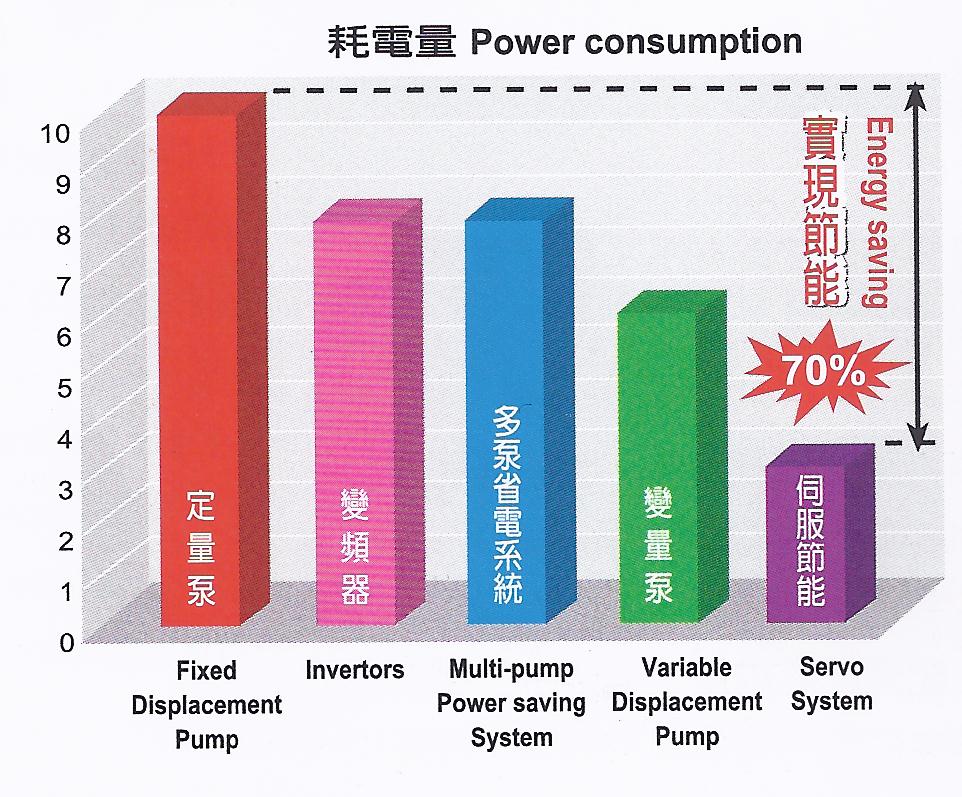

Test of Energy Efficiency

According to different products and molding conditions,

FCS servo power-saving injection molding machine can save 70%

more power than ordinary fixed pump injection molding machine,

and 40% than variable pump injection molding machine.

Remark: To achieve best performance of those power saving

system, production should under the conditions: Long hold

pressure time, long cooling time, and production speed slower

than 2~3 cycles under one minute, thick wall products. These

power saving systems will have outstanding efficiency.

total shots: 100

material: PP

mold: ruler

machine type: HN-100

| Items |

Unit |

Fixed displacement pump |

Multi-pump power saving

system |

Variable displacement

pump |

Servo system |

| Cycle time |

second |

16 |

17 |

16 |

16 |

| Product weight |

gram |

3.600g |

3.624g |

3.544g |

3.595g |

| Total weight |

gram |

360.0g |

362.4g |

354.4g |

359.5g |

| Power of consumption |

Kw/h |

3.5742 |

2.7137 |

1.8918 |

1.0940 |

| One hour power consumption |

Kw/h |

8.042 |

5.747 |

4.257 |

2.460 |

| One year power consumption |

Kw/h |

70447.9 |

50343.7 |

37291.3 |

21549.6 |

| One year electricity cost |

RMB |

56358.3 |

40275.0 |

29833.0 |

17239.7 |

| Power-saving

rate |

KWH/Kg |

9.92 |

7.49 |

5.34 |

3.04 |

| Power-saving

efficiency than standard pump |

¡@ |

/ |

24.08% |

47.07% |

69.39% |

Calculation condition: working for 24hr/day, 365

days; electricity charge:0.8RMB/KWH

Back to content

|